Essential PPE in the Food Industry: What You Need to Know

Overwhelmed by PPE options for food safety? Master your PPE selection for food workers safety with these practical tips.

Get 20€ off on your first order!

Did you know that the National Safety Council reports an annual total of over 53,000 foot injuries followed by a staggering 44.5 million injuries in the workplace caused by slips, trips and falls in the USA alone?

Each one of these statistics stands for a person whose life is affected, and it surely serves as a reminder of the importance of providing workers with the right safety footwear.

That being said, we know how challenging it can be to sift through the multitude of options available, decoding safety standards, and determining which materials are best suited for your unique work environment.

So, if you’re grappling with the challenge of selecting the ideal safety footwear for your workers, this guide will provide you with valuable insights into the factors to consider and the options available, ensuring that you make an informed and confident choice.

Here are the topics we will cover:

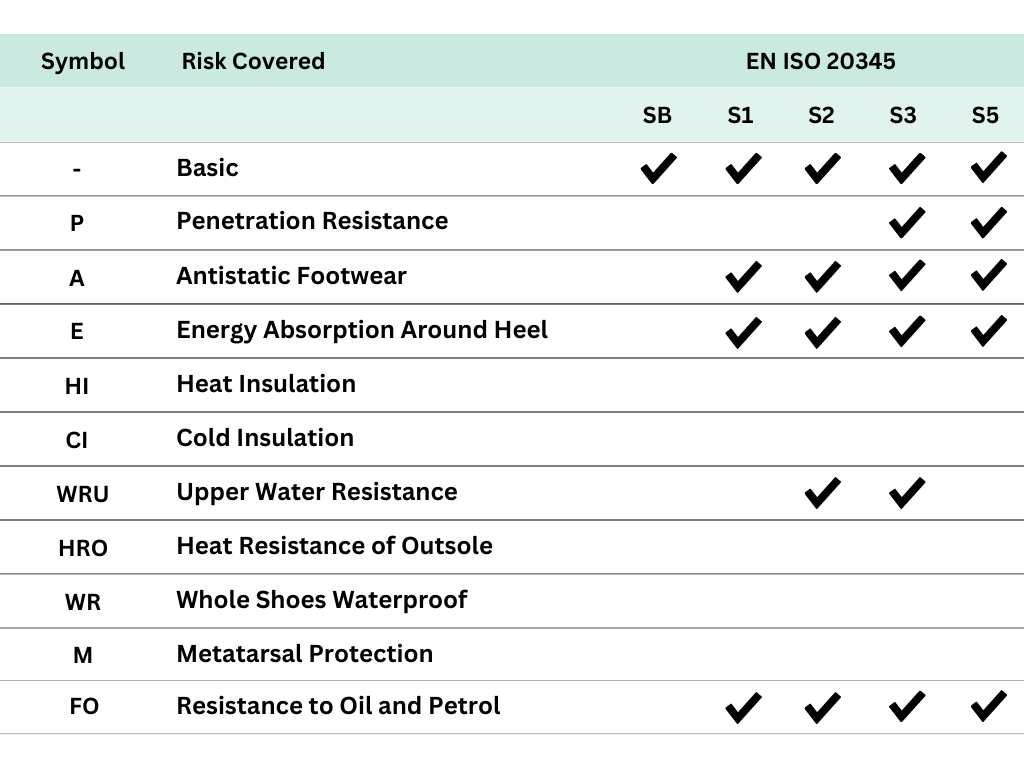

In Europe, the EN ISO 20345:2011 standard establishes the guidelines for safety shoes based on the required protection levels.

According to this classification, safety shoes are categorized into different classes, each offering distinct safety features:

Apart from these, safety shoe ratings also extend to the following protective attributes:

| Code | Attribute |

| P | Puncture resistance |

| C | Electrical resistance (non-conductive) |

| A | Electrical resistance (anti-static) |

| E | Energy-absorbing heel |

| HI | Heat insulation |

| CI | Cold insulation |

| WRU | Water-repellent uppers |

| HRO | Heat-resistant outsole |

For example, if your workers are operating in an environment where there is a risk of falling objects or foot impacts, then SB class shoes with a steel or composite toe cap would be appropriate. For those working in wet conditions or where there is a risk of electrocution, the waterproof and electrically resistant properties of S4 or S5 class shoes would be more suitable.

You can refer to the following table for more examples of use cases and the level of protection required. Please keep in mind that these are general guidelines. If you have doubts about the best safety class for your use cases, we warmly recommend getting in touch with our experts for a personal consultation.

Safety shoes are crafted from a range of materials, each selected for specific protective properties such as durability, impact resistance, and comfort.

Leather, known for its breathability and adaptability, is a go-to material. For instance, carpenters working in semi-controlled environments might opt for leather boots, benefiting from their form-fitting nature over time. Meanwhile, synthetic materials such as nylon or synthetic leather are lighter and more resistant to water and chemicals. Workers in chemical plants might prefer these, valuing the resistance against potential chemical spills.

Diving into protective elements, steel toe caps remain a top choice in industrial settings like construction sites where the risk of heavy objects falling is frequent. Composite toe caps, utilizing materials like carbon fibre, are preferred in electrical environments because they don’t conduct electricity. Meanwhile, warehouse workers, who need protection but also desire lightweight footwear for easy mobility, might lean towards aluminium toe caps.

When it comes to midsoles, EVA’s cushioning properties make it ideal for healthcare workers who stand for long shifts, offering them comfort throughout. Polyurethane (PU) is durable and absorbs shocks well, making it suitable for dock workers who handle heavy cargo and navigate uneven surfaces.

Concerning outsole materials, rubber‘s excellent grip is invaluable for factory workers, especially if they deal with oil-based machinery, given its resistance to oil. TPU, due to its combined resilience and strength, is especially favoured in rough terrains, such as on mining sites.

Lining materials cater to specific environments. Textile linings, with their breathable nature, are suitable for office settings with air-conditioning, ensuring comfort throughout the day. In contrast, forestry workers might opt for GORE-TEX® boots, appreciating its waterproof properties during rainy conditions.

For insoles, memory foam is a popular choice among retail workers. Spending hours on their feet, they benefit from the foam adapting to their foot shape. On the other hand, factory workers, who tread on hard concrete floors, might find gel insoles more comfortable due to their enhanced shock absorption.

Please notice that these are general recommendations, but we warmly recommend getting in touch with our experts to find the best options for your unique settings.

The key to selecting the right safety footwear is understanding the specific hazards faced by your workers, and this is done by conducting a thorough risk assessment, especially if your company employs a large number of employees working in diverse settings.

You (or your designated professional) can start with an on-site inspection to identify potential dangers. These can be:

After successfully identifying all potential hazards your employees might encounter, you can run an audit of your current safety footwear selection to ensure that it is both appropriate and that it complies with the latest safety standards.

Based on your findings, you might have to source new models that include the needed safety standards, while also taking into account your specific work needs and workers’ preferences.

While you’re gathering your workers’ feedback, also inquire about their preferred shoe cut. High-cut options (like work boots) offer added support around the ankle and Achilles tendon, making them well-suited for roles that require stability. Conversely, low-cut styles afford more ankle flexibility, ideal for jobs requiring frequent kneeling or bending. However, it’s worth mentioning that low-cut shoes offer less Achilles tendon protection.

As a last consideration, make sure you buy the correct size as ill-fitting shoes can cause discomfort and impair work efficiency. Always opt for safety shoes that don’t constrict your workers’ feet or press against their toes, especially around the toe caps. Also, keep in mind that feet can swell over long work hours, so a little extra room is generally a good idea. For this, we recommend initiating shoe fittings for a small group of employees and making the necessary size adjustments if needed.

More of this in the next section.

Selecting the right size is almost as important as selecting the right level of protection. After all, ill-fitting footwear will cause discomfort and in some cases, it can also lead to accidents, reduced productivity, and long-term health issues.

Here are some key points to help you make the right decision:

Men’s and women’s feet can greatly differ in shape, width, and size. This is why the right choice of safety footwear isn’t just a matter of size but of overall fit.

Generally speaking, women’s shoes are designed with a narrower heel and a wider forefoot compared to men’s shoes. Imagine a woman who typically wears a size 42 in men’s shoes. Even if you provide her with a men’s safety shoe, the fit won’t be ideal if the heel is too wide, causing her foot to slip out, or the forefoot is too narrow, causing discomfort. This woman might actually need a 41 in women’s sizes due to these differences in foot shape.

When it comes to sourcing, you should always make sure that the work shoes are available in sizes and widths suitable for both genders. This might mean sourcing from different suppliers. For example, you might need to order from a supplier that offers a specific line of safety shoes designed for women, in addition to the regular order of men’s safety shoes.

Different workplace environments come with specific hazards that require specialized protection.

Here are some examples of distinct workplace situations and the corresponding safety footwear features that you should consider:

Taking care of work shoes is a must to ensure their protective features last. However, no matter how well they’re looked after, even the best safety shoes on the market will reach a point where they need to be replaced.

Here are some indicators that it’s time to get a new pair:

In conclusion, routinely checking and caring for your work shoes helps them offer the best protection over their lifespan. If you observe signs of wear and tear, it’s time to get a new pair to stay safe and healthy on the job.

When looking for reliable industrial safety footwear suppliers in Europe, you should always consider factors such as product specs and fit, compliance with European safety regulations, and pricing. After all, procuring the best safety shoes for your use cases shouldn’t always break the bank.

This is where a wholesale marketplace like Droppe can make a difference.

Droppe’s catalogue includes 150,000 industrial SKUs from 100+ vetted European suppliers and it makes it easier than ever for you to compare their product selection, price, delivery time, and much more.

So, rather than spending countless hours negotiating with different work shoe suppliers, you now have their selections and offers in one single place. Plus, there are no geographical limitations, so your supplier pool will expand throughout Europe.

Additionally, as we know how hard it is to include multiple product specs and safety classes in your search, we’ve created user-friendly search filters to help you quickly locate all the relevant products in a few clicks – so, no time is wasted sourcing through the wrong shoe models.

Try Droppe today to find all the best work shoes from top-rated suppliers in Europe, or get in touch with our product experts for a custom quote tailored to your needs.

Choosing the best safety shoes for your workers is a decisive factor in safeguarding the well-being, health, and comfort of workers in diverse sectors. Given the myriad options available, it’s important to thoroughly assess your workplace’s unique needs, such as the hazards present and the duties of your staff.

Think about the height of the shoe cut, the sizing, and the protective features needed for your work setting. Verify that the selected safety shoes adhere to applicable safety standards, like the EN ISO 20345 norm in Europe. Regularly check and care for your work shoes to extend their lifespan and maximize their protective capabilities. When wear and tear become evident, replace the shoes.

Next, you can check our complete selection of safety shoes sourced from vetted European suppliers, or get in touch with our experts for a free consultation.

Thank you! You've signed up for our newsletter.

Overwhelmed by PPE options for food safety? Master your PPE selection for food workers safety with these practical tips.

Struggling to maintain clear vision in demanding environments? This guide is here to help. By the end, you’ll know exactly...

Electricians across Europe face unique challenges that require reliable safety glasses to ensure both protection and efficiency. Whether safeguarding against...

Overwhelmed by PPE options for food safety? Master your PPE selection for food workers safety with these practical tips.

Struggling to maintain clear vision in demanding environments? This guide is here to help. By the end, you’ll know exactly...

Electricians across Europe face unique challenges that require reliable safety glasses to ensure both protection and efficiency. Whether safeguarding against...

Get 10€ off on your first order!

Save 30% by buying directly from brands, and get an extra 10€ off orders over €100

Save 30% by buying directly form brands, and get an extra 10€ off orders over €100