What is the EN 13432 Standard?

Biodegradable packaging has become increasingly important in recent years as the world seeks more sustainable alternatives to traditional packaging materials....

Get 10€ off on your first order!

In professions and activities that demand prolonged exposure to harsh weather conditions, staying dry and comfortable is crucial. This is where the EN 343 standard comes into play. But what exactly is the EN 343 standard, and why is it so important? In this article, we delve into the specifics of EN 343, a European standard that defines the requirements for protective clothing against rain and inclement weather. We’ll explore the key aspects of the standard, what it means for workers and outdoor enthusiasts, and how you can identify clothing that meets these stringent requirements. Whether you’re in construction, agriculture, or simply enjoy outdoor adventures, understanding the EN 343 standard is essential for ensuring your gear provides the best possible protection against the elements. Read on to learn everything you need to know about this important standard.

Water Penetration Resistance, a crucial aspect of the EN 343 standard, is measured through the Hydrostatic Head Test as per the EN ISO 811 methodology. In this test, a fabric sample is secured over a cylinder filled with water, and the pressure is gradually increased until leakage is detected. The results classify the fabric into one of four levels based on its hydrostatic pressure resistance, measured in Pascals (Pa). Class 1 indicates a low resistance with a minimum of 8,000 Pa, Class 2 requires at least 13,000 Pa, Class 3 demonstrates higher resistance at 20,000 Pa, and Class 4 offers the highest resistance with a minimum of 30,000 Pa. This classification provides a clear understanding of how well a fabric can resist water penetration under increasing pressure, ensuring that protective clothing meets specific standards for waterproof performance.

Water Vapour Permeability, or breathability, is a key criterion within the EN 343 standard that determines how well a fabric allows moisture to escape. This is assessed using the Water Vapor Resistance (RET) test, following the EN ISO 11092 methodology. In this procedure, the fabric is placed over a heated, moisture-permeable plate, and the water vapor resistance (RET) is measured in square meters Pascal per watt (m²Pa/W). The results are classified into four levels based on the RET value. Class 1 represents low breathability with an RET value greater than 40 m²Pa/W, Class 2 indicates moderate breathability with values between 20 and 40 m²Pa/W, Class 3 reflects improved breathability with values between 10 and 20 m²Pa/W, and Class 4 provides the highest level of breathability with an RET value of 10 m²Pa/W or less. This classification helps in understanding the fabric’s ability to keep wearers dry from the inside, providing valuable guidance for selecting protective clothing that ensures both waterproofing and comfort.

The EN 343 standard also includes several optional tests that provide additional insights into the performance of protective clothing. These tests help evaluate aspects such as durability, dimensional stability, and overall garment integrity, offering manufacturers and users a comprehensive understanding of how the clothing will behave in challenging environments. Let’s explore each of these optional tests:

Wicking resistance is tested using the EN ISO 15380 method. A fabric strip is partially submerged in water, and the height to which the water rises by capillary action is measured. The results of this test evaluate the fabric’s resistance to wicking, ensuring that moisture does not travel through the fabric and compromise dryness.

Tensile strength is assessed using the ISO 13934-1 test method. In this procedure, fabric samples are pulled apart until they tear. The test indicates the fabric’s overall strength, providing an understanding of how well it can withstand pulling forces without breaking.

Tear resistance is evaluated using the ISO 4674-1 test method. Rectangular samples are notched and then subjected to a tearing force. This procedure evaluates the fabric’s resistance to tearing, which is crucial for assessing its durability and suitability in rugged environments.

Dimensional change is tested using the ISO 5077 method. The fabric is measured before and after washing/drying to identify any changes in dimensions. The results indicate shrinkage or stretching, ensuring that the fabric maintains its intended fit and size after repeated washes.

Seam strength is tested using the ISO 13935-2 method. In this test, a seam sample is subjected to tensile force until the seam breaks. The results evaluate the durability of seams, providing insights into the overall construction quality and integrity of the garment.

Garment testing is conducted using the whole garment rain tower test method outlined in EN 14360. In this procedure, the garment is worn by a mannequin and exposed to simulated rain in a controlled environment. The test checks for leaks in the finished garment, ensuring that the entire piece provides comprehensive protection against rain and inclement weather.

These optional tests offer a comprehensive view of the performance characteristics of protective clothing beyond the core requirements of the EN 343 standard, helping manufacturers refine their designs and ensuring users have the best possible protection in demanding conditions.

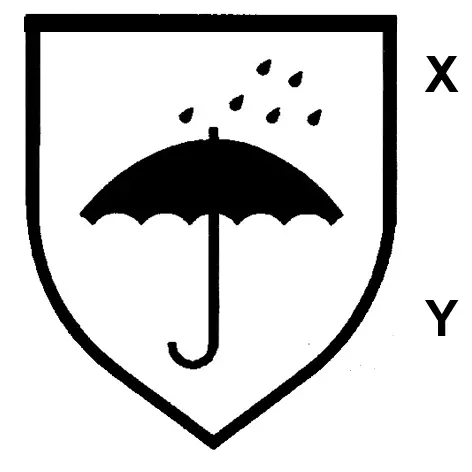

Understanding the test result markings on EN 343-certified garments is crucial for selecting the appropriate protective clothing. The EN 343 marking consists of two numbers, written as “EN 343: X, Y”. The first number, “X,” indicates the Water Penetration Resistance class, ranging from 1 to 4, with 1 representing low resistance (≥ 8,000 Pa) and 4 offering high resistance (≥ 30,000 Pa). The second number, “Y,” denotes the Water Vapour Permeability (Breathability) class, ranging from 1 to 4, where 1 signifies low breathability (RET > 40 m²Pa/W) and 4 signifies high breathability (RET ≤ 10 m²Pa/W). Some garments may also display additional symbols to indicate optional test results, such as seam strength, dimensional change, and tear resistance. By understanding these markings, users can make informed decisions about the suitability of protective clothing for specific weather conditions and work environments, ensuring optimal safety and comfort.

| Marking | Description |

|---|---|

| X | Water Penetration Resistance Class |

| – Class 1: ≥ 8,000 Pa (Low Resistance) | |

| – Class 2: ≥ 13,000 Pa | |

| – Class 3: ≥ 20,000 Pa | |

| – Class 4: ≥ 30,000 Pa (High Resistance) | |

| Y | Water Vapour Permeability (Breathability) Class |

| – Class 1: RET > 40 m²Pa/W (Low Breathability) | |

| – Class 2: 20 < RET ≤ 40 m²Pa/W | |

| – Class 3: 10 < RET ≤ 20 m²Pa/W | |

| – Class 4: RET ≤ 10 m²Pa/W (High Breathability) | |

| Additional Symbols | Optional Tests |

| Wicking Resistance (Clause 4.4) | Assessed using EN ISO 15380, measures fabric resistance to water absorption by capillary action |

| Tensile Strength (Clause 4.5) | Assessed using ISO 13934-1, indicates fabric strength |

| Tear Resistance (Clause 4.6) | Assessed using ISO 4674-1, evaluates fabric resistance to tearing |

| Dimensional Change (Clause 4.7) | Assessed using ISO 5077, indicates fabric shrinkage or stretching after washing/drying |

| Seam Strength (Clause 4.8) | Assessed using ISO 13935-2, evaluates the durability of seams |

| Garment Testing (Clause 4.3) | Conducted using EN 14360, checks for leaks in the finished garment during simulated rain |

Products adhering to the EN 343 standard are widely used in industries and activities where workers and individuals face prolonged exposure to rain and harsh weather conditions. For instance, construction workers rely on EN 343-certified jackets and pants to stay dry while working on open-air building sites. In agriculture, farmers wear waterproof and breathable overalls during rainy seasons to ensure protection and comfort in the fields. Logistics personnel, such as truck drivers and delivery workers, depend on these garments to maintain productivity despite changing weather conditions. Additionally, utility workers repairing power lines or maintaining infrastructure in stormy weather benefit from EN 343 gear that offers both water resistance and breathability. Outdoor enthusiasts, like hikers and campers, also use this standard to choose rainproof clothing that allows them to enjoy their adventures while staying protected. Overall, the EN 343 standard is critical for anyone requiring reliable weather protection in wet and windy environments.

The EN 343 standard plays a vital role in ensuring that protective clothing provides effective and reliable protection against rain and adverse weather conditions. By understanding the classifications of Water Penetration Resistance and Water Vapour Permeability (Breathability), along with the optional tests like Wicking Resistance, Tensile Strength, and Garment Testing, you can make informed choices when selecting gear. Whether you’re in construction, agriculture, logistics, or simply enjoy outdoor activities, choosing clothing that meets EN 343 standards ensures optimal safety, comfort, and durability. With this comprehensive guide to the EN 343 standard, you are now equipped to confidently interpret test result markings and choose the right gear that meets your specific needs in challenging weather conditions. Stay dry, stay comfortable, and be ready for whatever the elements throw your way.

Thank you! You've signed up for our newsletter.

Biodegradable packaging has become increasingly important in recent years as the world seeks more sustainable alternatives to traditional packaging materials....

Safety is a definite concern in industries where employees are exposed to hazardous conditions. Safety footwear plays a critical role...

ISO 22000 is an internationally recognized standard that sets the requirements for a Food Safety Management System (FSMS). Designed to...

Biodegradable packaging has become increasingly important in recent years as the world seeks more sustainable alternatives to traditional packaging materials....

Safety is a definite concern in industries where employees are exposed to hazardous conditions. Safety footwear plays a critical role...

ISO 22000 is an internationally recognized standard that sets the requirements for a Food Safety Management System (FSMS). Designed to...

Get 10€ off on your first order!

Save 30% by buying directly from brands, and get an extra 10€ off orders over €100

Save 30% by buying directly form brands, and get an extra 10€ off orders over €100