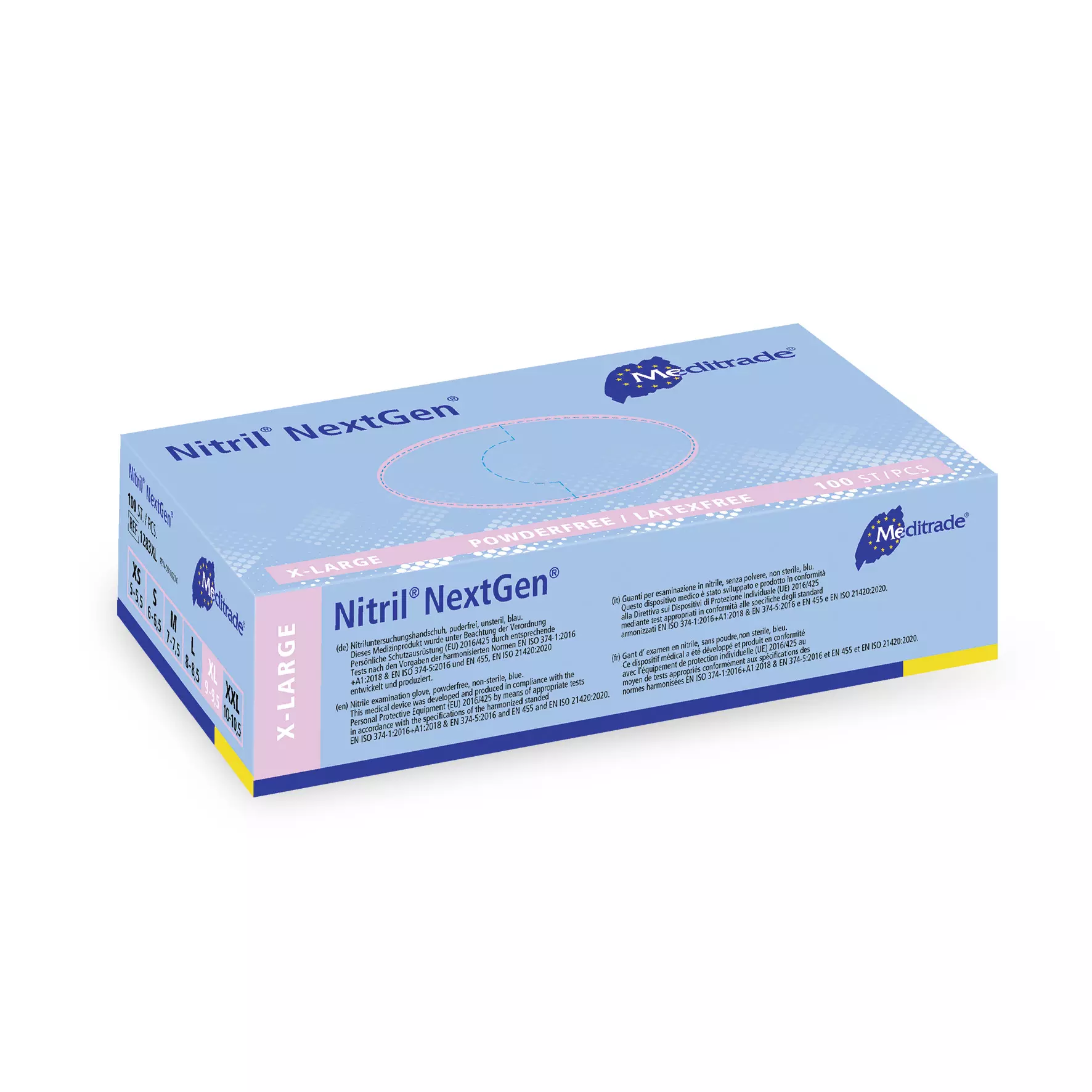

Meditrade Nitril® NextGen® Nitrile Examination Glove, Powder-Free

Meditrade Nitril® NextGen® Nitrile Examination Glove, Powder-Free

(28)

Features You'll Love

Cuff Style · Rolled

The design of the wrist opening, affecting ease of putting gloves on, comfort, and how securely they stay in place during use.

The design of the wrist opening, affecting ease of putting gloves on, comfort, and how securely they stay in place during use.

The design of the wrist opening, affecting ease of putting gloves on, comfort, and how securely they stay in place during use.

Fingertips · Textured

Describes the surface texture of the fingertip area, affecting grip strength and tactile sensitivity during use.

Describes the surface texture of the fingertip area, affecting grip strength and tactile sensitivity during use.

Describes the surface texture of the fingertip area, affecting grip strength and tactile sensitivity during use.

Meditrade

Nitril® NextGen® Nitrile Examination Glove, Powder-Free, 10 x 100 pcs

Nitril® NextGen® Nitrile Examination Glove, Powder-Free, 10 x 100 pcs

(28)

36,87 €

Price per 10 packages (1 000 pcs)

3,69 € / 100 pcs

Free delivery

Features You'll Love

Cuff Style · Rolled

The design of the wrist opening, affecting ease of putting gloves on, comfort, and how securely they stay in place during use.

The design of the wrist opening, affecting ease of putting gloves on, comfort, and how securely they stay in place during use.

The design of the wrist opening, affecting ease of putting gloves on, comfort, and how securely they stay in place during use.

Fingertips · Textured

Describes the surface texture of the fingertip area, affecting grip strength and tactile sensitivity during use.

Describes the surface texture of the fingertip area, affecting grip strength and tactile sensitivity during use.

Describes the surface texture of the fingertip area, affecting grip strength and tactile sensitivity during use.

Product description

The product description has not been specified

The product description has not been specified

The product description has not been specified

Describes the surface texture of the fingertip area, affecting grip strength and tactile sensitivity during use.

Measures the thickness of the glove's wrist/forearm extension, affecting durability, tear resistance, and protection level during use.

Your go-to gloves for diverse tasks, offering reliable protection and convenience across many applications.

Complete finger coverage ensures full protection and hygiene for your hands, maintaining dexterity for all tasks.

Protects sensitive surfaces from silicone contamination, ensuring product integrity and quality.

Easily wear on either hand, ensuring quick protection and less waste.

Gentle on sensitive skin, these gloves are free from common chemical accelerators, reducing irritation for comfortable, worry-free wear.

The visual appearance of the glove material, ranging from basic colors to specialized options for different professional and aesthetic preferences.

The texture of the glove exterior, affecting grip strength and handling capability for different tasks and working conditions.

The design of the wrist opening, affecting ease of putting gloves on, comfort, and how securely they stay in place during use.

Indicates how long gloves maintain their protective properties and quality when stored properly, typically measured in years from manufacture date.

Indicates the maximum percentage of defective gloves acceptable in quality testing, with lower numbers representing higher quality standards.

Indicates whether gloves contain powder on the interior surface to aid donning, affecting ease of use and contamination control requirements.

Measures the material thickness at the palm area, affecting protection level and tactile sensitivity during use.

Measures how far the glove extends up the wrist and forearm, determining the level of coverage and protection provided during use.

Measures the material thickness at the fingertips, affecting tactile sensitivity, dexterity, and protection level during use.

- Medical Protection

- Antimicrobial Protection

- Hand Protection

- Clean Room

- Food Service

Protective gloves with the EN 374-4:2013 rating are tested for their resistance to degradation by chemicals. This measures changes in the glove material, like swelling or hardening, ensuring the glove maintains its protective qualities when exposed to hazardous substances.

Test results

This glove's material resists breaking down when in contact with specific chemicals. This helps protect you from physical changes to the glove like swelling, cracking, or softening that could compromise your safety during use.

Protective gloves with the EN ISO 21420:2020 rating are tested for general requirements, including design, construction, the absence of harmful chemicals, correct sizing, and dexterity. This ensures the gloves are safe and comfortable to wear, fit correctly, and won't cause adverse skin reactions.

Protective gloves with the EN 374-1 rating are tested for their ability to resist dangerous chemicals and micro-organisms, including how well they prevent leaks, chemical breakthrough, and material degradation. This rating helps you select gloves that provide certified protection for your hands when working with hazardous substances.

Gloves with the EN 374-5:2016 rating are tested for resistance to penetration by bacteria and fungi, and potentially viruses. This means the gloves provide a protective barrier against microorganisms, helping to keep your hands safe from harmful biological agents.

Test results

This product protects you from bacteria and fungi. It passed leakage tests, making it a reliable barrier when handling materials where these micro-organisms are a risk, such as in cleaning or laboratory work.

Gloves with the EN 374-2:2014 rating are tested for their resistance to penetration, ensuring liquids and microorganisms do not leak through tiny holes or imperfections. This means the gloves provide an effective barrier, protecting your hands from direct contact with hazardous chemicals and microbes.

Test results

This product has passed a leak test to ensure it is a waterproof and effective barrier against liquids, bacteria, and fungi. This protects your hands from contact with harmful microorganisms in various work environments.

Medical gloves with the EN 455-3:1999 rating are tested for biological safety, specifically evaluating levels of proteins and leachable substances. This ensures the gloves minimize potential allergic reactions and harmful effects for both the wearer and patient, providing peace of mind.

Test results

This product has been tested for biological safety to ensure it is safe for skin contact. It minimizes the risk of adverse reactions from chemicals, latex proteins, and other residues used during manufacturing.

Medical gloves with the EN 455-2:2009 rating are tested for their physical properties, such as strength, stretch, and dimensions. This ensures the gloves are durable and reliable, providing effective protection against cross-contamination for both the user and the patient.

Test results

This glove has been tested for physical strength and durability to ensure it won't tear or break easily during use. It provides reliable protection from cross-contamination for both the wearer and the patient in medical situations.

Medical gloves with the EN 455-1:2020 rating are tested for freedom from holes using a water tightness test. This ensures the gloves provide a reliable barrier, protecting you from cross-contamination and the spread of infections.

Test results

This rating indicates the glove's quality and resistance to pinholes, which is tested by filling it with water. A lower AQL number means a lower chance of defects, providing a more reliable barrier against microorganisms.

Single-use medical gloves with the EN 455-4:2009 rating are tested for their shelf life, ensuring they maintain properties like strength and barrier integrity over time. This means the gloves will remain effective and safe, providing reliable protection against infections until their expiration date when stored correctly.

Medical devices with the ISO 13485:2016 rating are tested for a quality management system that ensures consistent safety, quality, and regulatory compliance throughout their lifecycle. This provides assurance that the product is reliably produced to high international standards for patient use.

Test results

This product was made under a quality management system that ensures consistent design, production, and distribution. This focuses on the safety, performance, and regulatory compliance of medical devices throughout their entire lifecycle, from design to disposal.

MD stands for "Medical Device." It refers to any instruments, apparatus, machines, implants, or other similar or related articles that are intended to be used for human beings for the purpose of diagnosis, prevention, monitoring, treatment or alleviation of disease, injury or disability. In Europe, a MD Label is a special label that must be on all Medical Devices that are sold or used in the European Union (EU). The label must include information about the product, such as the name of the manufacturer, the intended use of the product and CE mark. To be able to sell or use a Medical Device in the EU, the device must meet certain standards and requirements set by the European Union and notified body.

PPE stands for "personal protective equipment." PPE Category 3 refers to equipment that is complex and provide the highest level of protection such as powered respirators, SCBA, and full body suits. In Europe, PPE Category 3 must meet certain safety standards set by the European Union, which means that it must be designed and manufactured to protect the user without causing harm. Companies that make or sell PPE must prove that it meets these standards. They also must have a quality management system in place, have to be audited regularly by a notified body and have to have a technical documentation.

Food safe refers to the safety of food products that are used or consumed by people. In Europe, food safety is regulated by the European Union (EU) and the European Food Safety Authority (EFSA). These organizations set standards and requirements for food products to ensure they are safe to eat. To be considered "food safe" in Europe, a product must meet these standards and be free of harmful substances. This includes being free of harmful bacteria, pesticides, and other contaminants. Food products that do not meet these standards cannot be sold or used in the EU.

Free delivery for all Meditrade products