When it comes to selecting protective gloves, understanding the EN388 standard is crucial. This European safety benchmark provides specific criteria for evaluating the resistance of gloves to mechanical risks, ensuring that users have the right level of protection for their tasks. In this article, we’ll break down what EN388 covers, explain the rating system, and help you choose the best gloves for your needs. Whether you work in construction, manufacturing, or another industry with hand hazards, this guide will clarify the essentials of EN388 so you can make informed decisions.

Abrasion Resistance Explained

Abrasion resistance measures a glove’s ability to endure wear over time. The testing method employs a Martindale tester, fitted with standardized abrasive paper (Klingspor PL31B 180 grit). Circular samples of the glove material are abraded under a pressure of 9 kPa until a hole appears. The glove is then rated on a scale from 1 to 4, based on the number of cycles required to produce a hole, with higher ratings indicating superior resistance.

Cut Resistance (Coup Test) Explained

The cut resistance (Coup Test) assesses a glove’s ability to withstand cuts. In this test, a circular rotating blade moves back and forth across a sample of the glove material under a constant load. The blade continues until it slices through the material. After, the cut index is then calculated by comparing the number of cycles required to cut through the test material against a reference fabric. Gloves are rated from 1 to 5, with higher numbers indicating greater cut resistance.

Tear Resistance Explained

Tear resistance measures a glove’s durability and protection against tearing. In the test, rectangular strips of the glove material are pulled apart using a tensile testing machine. The force required to tear the sample is measured, and the glove is rated from 1 to 4 based on the maximum force needed to tear it, with higher numbers indicating better resistance.

Puncture Resistance Explained

Puncture resistance evaluates a glove’s protection against pointed objects. The test employs a puncture probe with a diameter of 4.5 mm, driven through the glove material at a specified speed using a tensile testing machine. The force required to puncture the sample is measured, and the glove is rated from 1 to 4 based on this force, with higher ratings indicating stronger puncture resistance.

Cut Resistance (ISO 13997 Test) Explained

Cut resistance, as per the ISO 13997 test, gauges a glove’s protection against sharp objects. In this method, a straight-edge blade is moved across the sample with increasing force until it cuts through. The force required to make a single pass through the material is measured and recorded in Newtons (N). Gloves are rated from A to F, with higher letters indicating better cut resistance.

Impact Resistance Explained

Impact resistance evaluates a glove’s ability to protect against blunt force impacts. In this test, specific sections of the glove, such as knuckle guards, are subjected to a falling weight. A defined mass is dropped onto the sample, and the force transmitted through the glove is measured. The glove either passes or fails based on whether the transmitted force is less than or equal to 7 kN. This criterion helps determine the glove’s effectiveness in protecting against high-impact forces.

How to Read the Test Result Markings of EN388

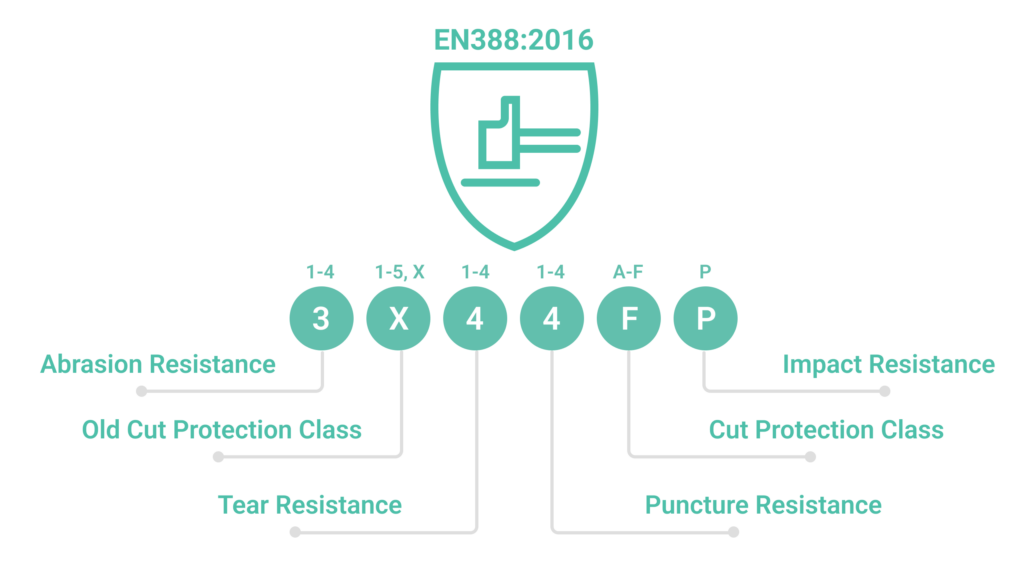

The EN388 standard assigns a series of numbers and letters to indicate a glove’s performance across various mechanical tests. The markings follow this format: EN388:2016 X1X2X3X4X5, where each character represents a specific test result:

- Abrasion Resistance (X1): Rated from 1 to 4, with higher numbers indicating better abrasion resistance.

- Cut Resistance (Coup Test, X2): Rated from 1 to 5, reflecting the glove’s resistance to cuts.

- Tear Resistance (X3): Rated from 1 to 4, showing how well the glove resists tearing.

- Puncture Resistance (X4): Rated from 1 to 4, indicating the glove’s puncture resistance.

- Cut Resistance (ISO 13997, X5): Rated from A to F, providing an alternative measure of cut resistance using the ISO 13997 test.

- Impact Resistance (optional, P): Marked with ‘P’ if the glove meets the impact resistance requirement.

If a test isn’t applicable, it is marked as “X” in that position. Understanding these markings ensures you select the appropriate gloves for your specific needs.

| Test | Rating | Protection Level |

|---|---|---|

| Abrasion Resistance | 1 | Low |

| 2 | Moderate | |

| 3 | High | |

| 4 | Very High | |

| Cut Resistance (Coup Test) | 1 | Low |

| 2 | Moderate | |

| 3 | High | |

| 4 | Very High | |

| 5 | Maximum | |

| Tear Resistance | 1 | Low |

| 2 | Moderate | |

| 3 | High | |

| 4 | Very High | |

| Puncture Resistance | 1 | Low |

| 2 | Moderate | |

| 3 | High | |

| 4 | Very High | |

| Cut Resistance (ISO 13997) | A | Very Low |

| B | Low | |

| C | Moderate | |

| D | High | |

| E | Very High | |

| F | Maximum | |

| Impact Resistance | P | Pass (≤ 7 kN) |

Where Are Products with EN388 Standard Used?

Products meeting the EN388 standard are widely used across various industries where hand protection is crucial. In construction, these gloves protect workers from abrasion and punctures while handling rough materials like bricks and metal. Manufacturing employees use them to guard against cuts and tears when operating machinery or assembling products. In the automotive industry, they provide essential protection against sharp tools and parts during vehicle maintenance and repair. Additionally, waste management workers rely on them for puncture resistance while sorting and handling waste. These gloves are also commonly used in logistics and warehousing, where they help prevent injuries from repetitive handling of heavy and abrasive packages.

Conclusion

Understanding the EN388 standard is essential for selecting the right protective gloves for your specific needs. This European benchmark provides comprehensive ratings across key mechanical risks like abrasion, cut, tear, puncture, and impact resistance. By decoding the EN388 markings, you can make an informed choice that ensures optimal hand protection in your industry, whether it’s construction, manufacturing, automotive, or waste management. With this knowledge, you can confidently choose gloves that offer the right balance of protection and performance, keeping your hands safe while you work.