How To Choose The Right Material For Takeaway Boxes: Cardboard, Plastic, Or Compostable Options

Struggling to find the perfect takeaway box for your food service business? Whether you’re deciding between cardboard, plastic, or compostable...

Get 20€ off on your first order!

In industrial settings, keeping the area clean is important for safety, productivity, and following the rules. The industrial sector in Europe has to follow strict rules, so it’s important for facility managers and operators to know how to clean things properly and put them into action. This guide describes the most important types of industrial cleaners, how they can be used, the benefits they offer, and important safety rules.

Cleaners made for industrial settings are specially made to work in tough conditions. These products are made to get rid of heavy dirt, oil, grease, and other residues that tend to build up in factories, warehouses, and other industrial places. By using the right cleaners, you can:

Industrial cleaners vary depending on the nature of the cleaning tasks and the materials to be cleaned. Here are some of the main categories:

/package

/package

/piece

/piece

/package

/package

/piece

/piece

/piece

/piece

/piece

/piece

/piece

Degreasers are meant especially to eliminate grease, oil, and other lubricants. Often used in food processing, manufacturing, and automotive sectors, they assist to guarantee that floors and machinery are clear of slippery residues.

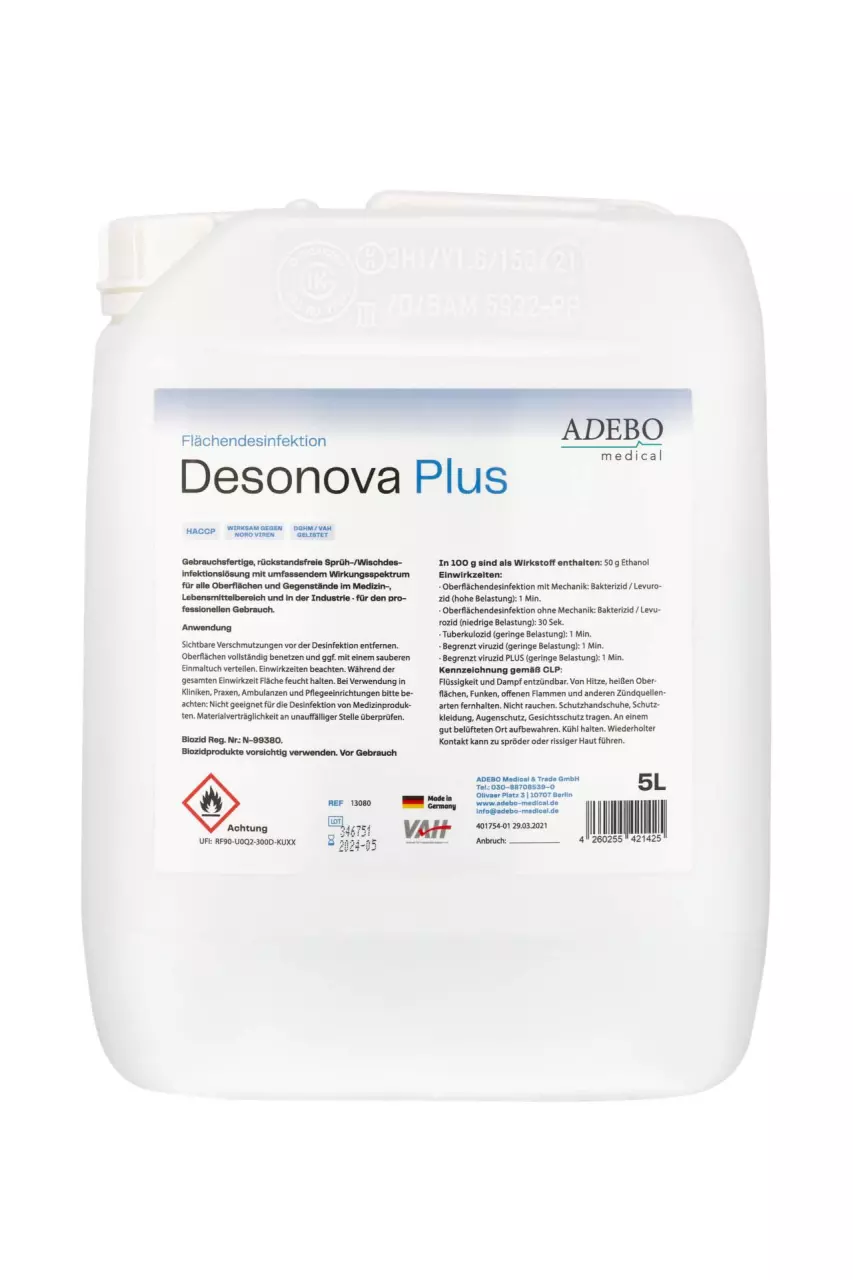

Disinfectants and sanitizers are critical for maintaining hygienic environments, especially in industries like food processing, pharmaceuticals, and healthcare manufacturing.

Descalers are used to remove limescale, a common issue in industrial facilities with water-based systems. By preventing scale buildup, they help improve the efficiency of machinery like boilers, cooling towers, and piping systems.

Industrial floor cleaners are designed to handle heavy-duty cleaning in high-traffic areas. These can include scrubbers, polishers, and general-purpose floor detergents.

Cleaners that use solvents break down and get rid of organic toxins like glues, oils, and resins. Because they work well on metals, plastics, and ceramics, they are popular in the automotive, metalworking, and electronics industries.

Picking the right industrial cleaner depends on a number of things, such as the contaminants that are present, the material of the surface, and environmental concerns. Take a look at these important points:

When using industrial cleaners, you have to follow strict safety rules. Here are the main things to think about:

Industrial cleaners often contain strong chemicals, so employees should wear appropriate PPE, including gloves, eye protection, and, in some cases, respirators.

Some industrial cleaners release fumes that can be harmful if inhaled in enclosed spaces. Proper ventilation or the use of extraction systems can reduce the risk of respiratory issues.

Environmental rules must be followed when getting rid of industrial cleaning trash. There are specific ways to get rid of many cleaners, especially ones that contain solvents. Check local rules to make sure you’re following them and to keep the earth from getting hurt.

To keep an industrial facility consistently clean, create a well-defined cleaning schedule:

European businesses must follow a number of rules about keeping the workplace clean and keeping chemicals safe:

Technological advancements continue to shape the industrial cleaning sector. Emerging trends include:

How often you clean relies on how the equipment is used and the type of business. Heavy machines and places with a lot of foot traffic may need to be cleaned every day, while other areas may only need to be cleaned once a week or once a month.

Yes, many companies offer biodegradable, water-based cleaners that are safer for the environment and still effective in industrial settings.

Mislabeling, improper storage, and failure to wear protective equipment are frequent errors. Ensuring staff is trained and informed can prevent these issues.

While not all cleaners pose significant risks, wearing PPE like gloves and eye protection is generally recommended to avoid direct contact with chemicals.

Only cleaners labeled as food-safe should be used in food processing environments. Check labels and choose products approved for these settings.

By choosing the right industrial cleaners, following safety rules, and following European laws, facility managers can make sure that the workplace is safe and productive. Always look for products that meet both the cleaning needs of the industry and the environmental and safety standards expected in Europe.

Thank you! You've signed up for our newsletter.

Struggling to find the perfect takeaway box for your food service business? Whether you’re deciding between cardboard, plastic, or compostable...

Choosing the right disposable forks is key to enhancing customer satisfaction, streamlining operations, and supporting sustainability. This guide simplifies your...

Not sure whether liquid or powder dishwasher detergent is right for you? This article will help you decide by comparing...

Struggling to find the perfect takeaway box for your food service business? Whether you’re deciding between cardboard, plastic, or compostable...

Choosing the right disposable forks is key to enhancing customer satisfaction, streamlining operations, and supporting sustainability. This guide simplifies your...

Not sure whether liquid or powder dishwasher detergent is right for you? This article will help you decide by comparing...

Get 10€ off on your first order!

Save 30% by buying directly from brands, and get an extra 10€ off orders over €100

Save 30% by buying directly form brands, and get an extra 10€ off orders over €100