Features You'll Love

Fingertips · Textured

Describes the surface texture of the fingertip area, affecting grip strength and tactile sensitivity during use.

124,74 €

Price per 10 packages (500 pcs)

24,95 € / 100 pcs

Free delivery

Features You'll Love

Fingertips · Textured

Describes the surface texture of the fingertip area, affecting grip strength and tactile sensitivity during use.

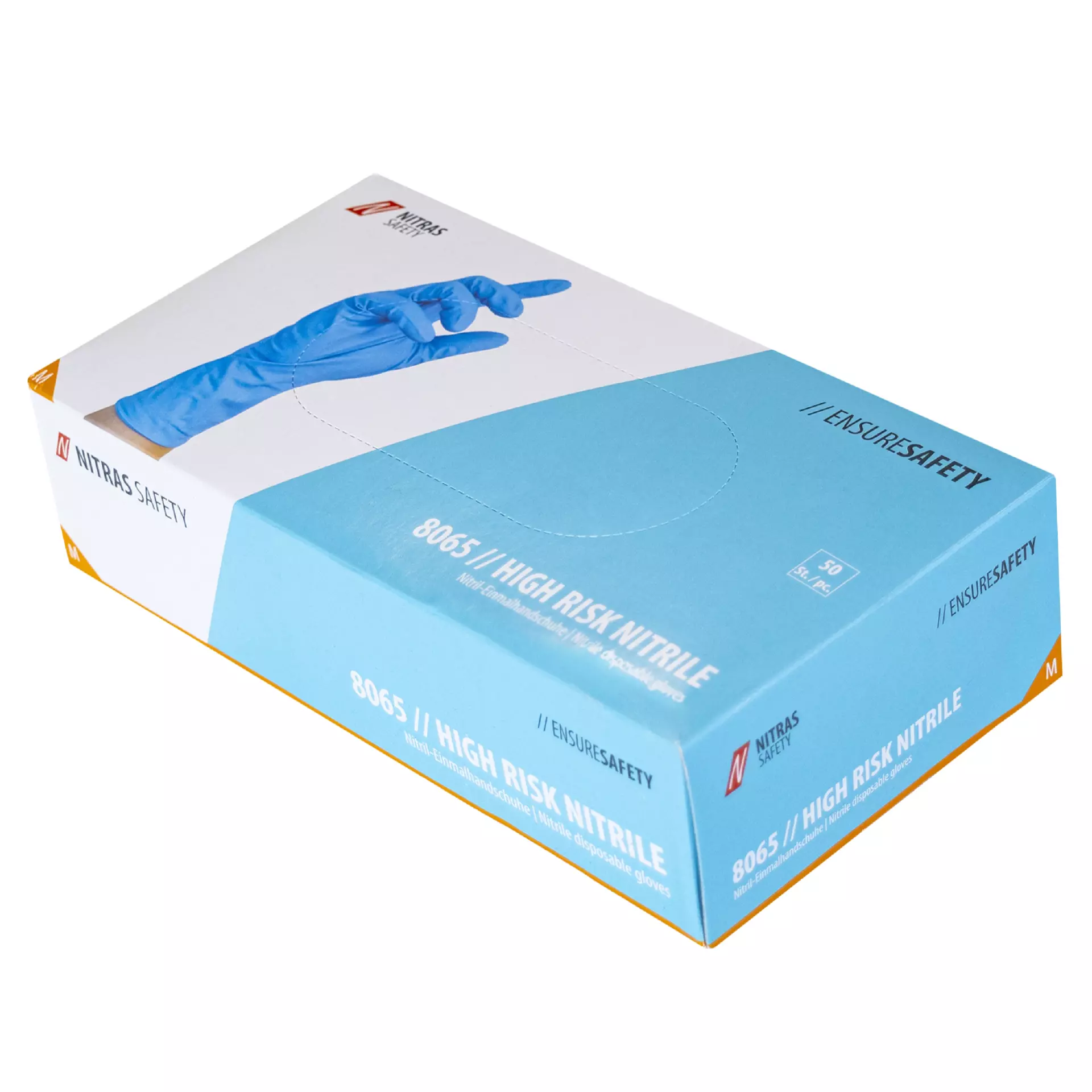

Product description

Premium disposable nitrile gloves designed for high-risk applications requiring superior protection against chemicals, micro-organisms, bacteria, and viruses. These gloves feature micro-roughened fingertips for enhanced grip and rolled edges for added comfort, while meeting multiple EN and ISO safety standards. The ambidextrous design and powder-free construction make them ideal for food contact and various industrial applications requiring precision handling.

Product Features

- Powder-free construction with rolled edge

- Micro-roughened fingertips for improved grip

- Ambidextrous design for versatile use

- Premium quality with AQL 0.65

- Food contact safe

Technical Details

- Material thickness varies by zone:

- Finger: 0.28mm

- Palm: 0.20mm

- Cuff: 0.14mm

- Length: approximately 280mm

Standards

- EN 388:2016+A1:2018 (2001X)

- EN ISO 374-1:2016/Type A (JKLOPT)

- EN ISO 374-5:2016 VIRUS protection

- EN 420:2003 + AC:2009 (Dexterity Level 5)