Features You'll Love

Toe Cap Material · Composite, Aluminum

Outsole Properties · Anti Slip

Anti-slip soles provide superior grip, keeping you safe and steady on challenging surfaces.

Outsole Properties · Oil Resistant

Closure Style · Spin Lock

Oil-resistant soles ensure secure footing and lasting durability in oily environments.

The method used to secure the shoe to your foot, affecting how easy it is to put on and take off.

EN 61340-5-1 · Electrostatic Discharge Antistatic

Guards the product’s sensitive electronics against damage from static electricity. This protection during manufacturing and handling prevents hidden component failure, ensuring your device works reliably and has a longer operational life.

201,68 €

Choose size

Free delivery

Features You'll Love

Toe Cap Material · Composite, Aluminum

Outsole Properties · Anti Slip

Anti-slip soles provide superior grip, keeping you safe and steady on challenging surfaces.

Outsole Properties · Oil Resistant

Closure Style · Spin Lock

Oil-resistant soles ensure secure footing and lasting durability in oily environments.

The method used to secure the shoe to your foot, affecting how easy it is to put on and take off.

EN 61340-5-1 · Electrostatic Discharge Antistatic

Guards the product’s sensitive electronics against damage from static electricity. This protection during manufacturing and handling prevents hidden component failure, ensuring your device works reliably and has a longer operational life.

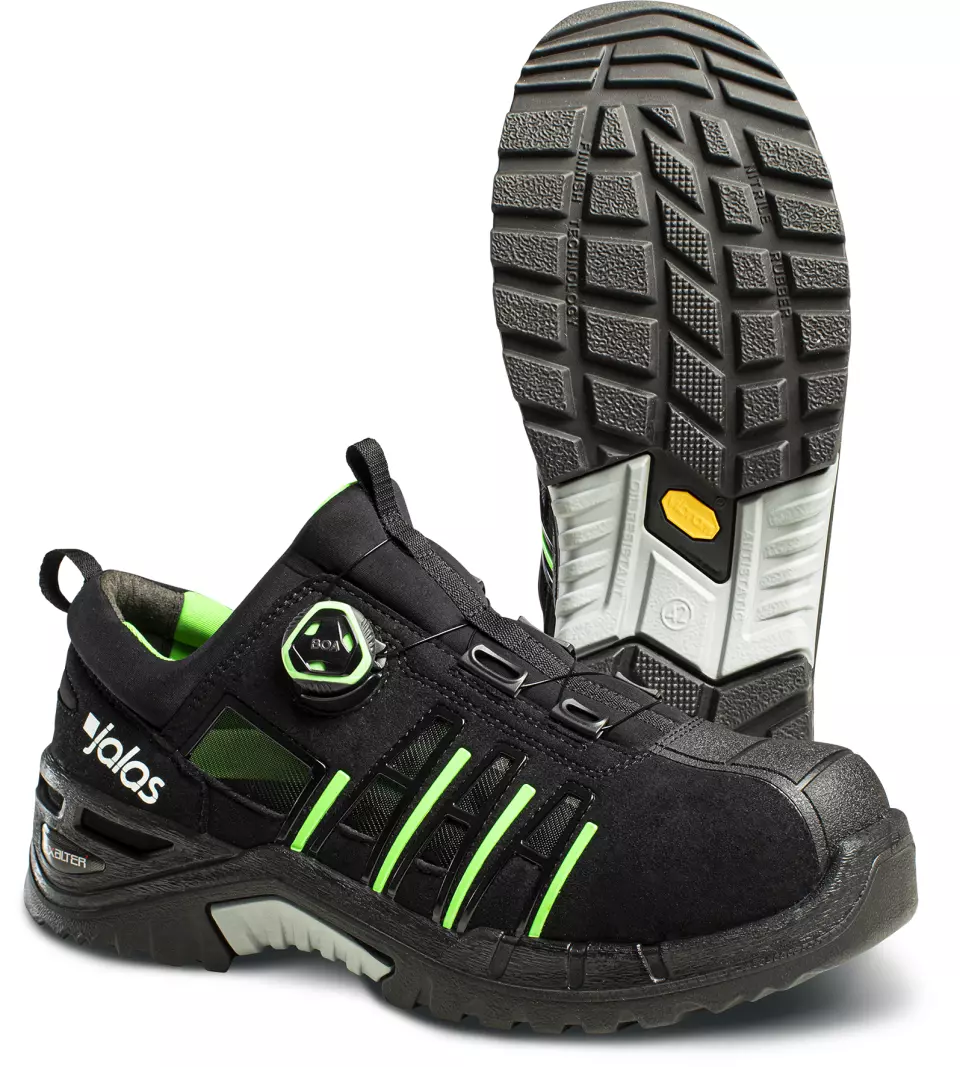

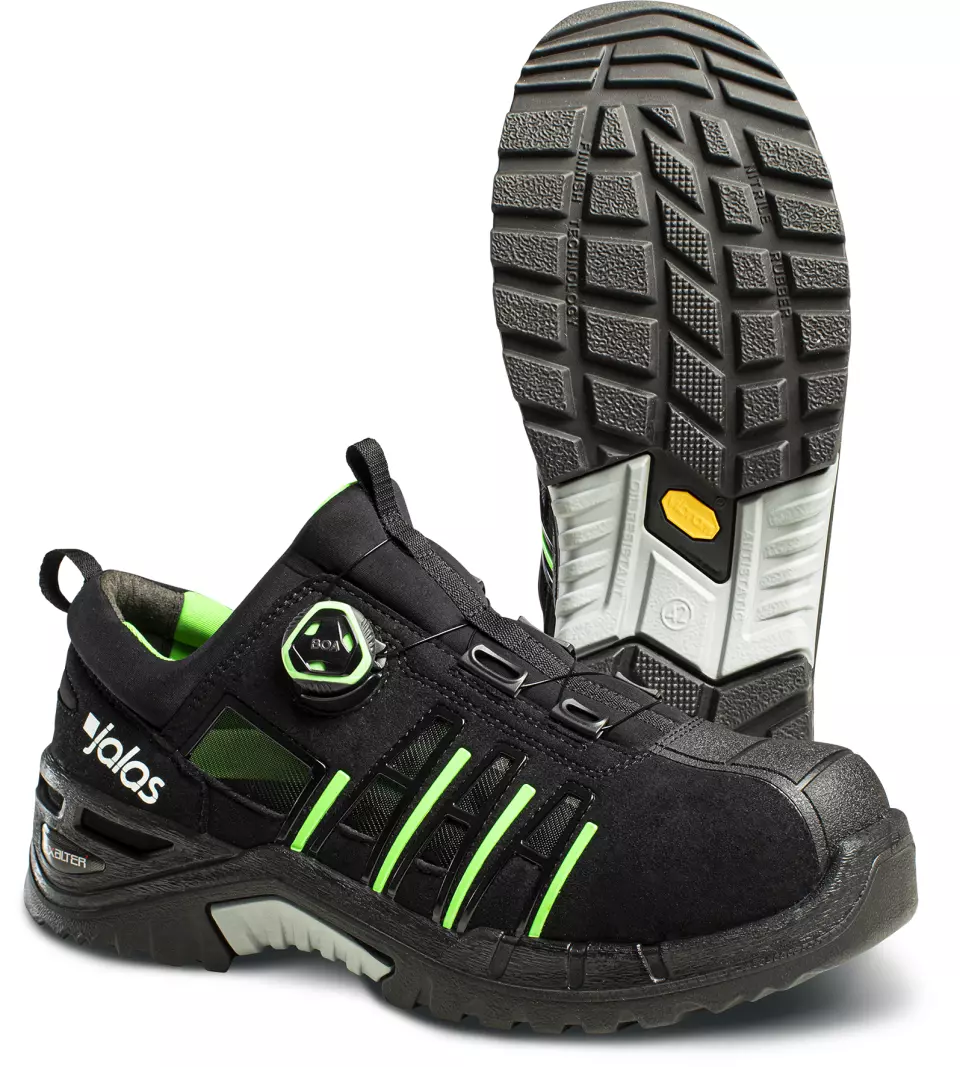

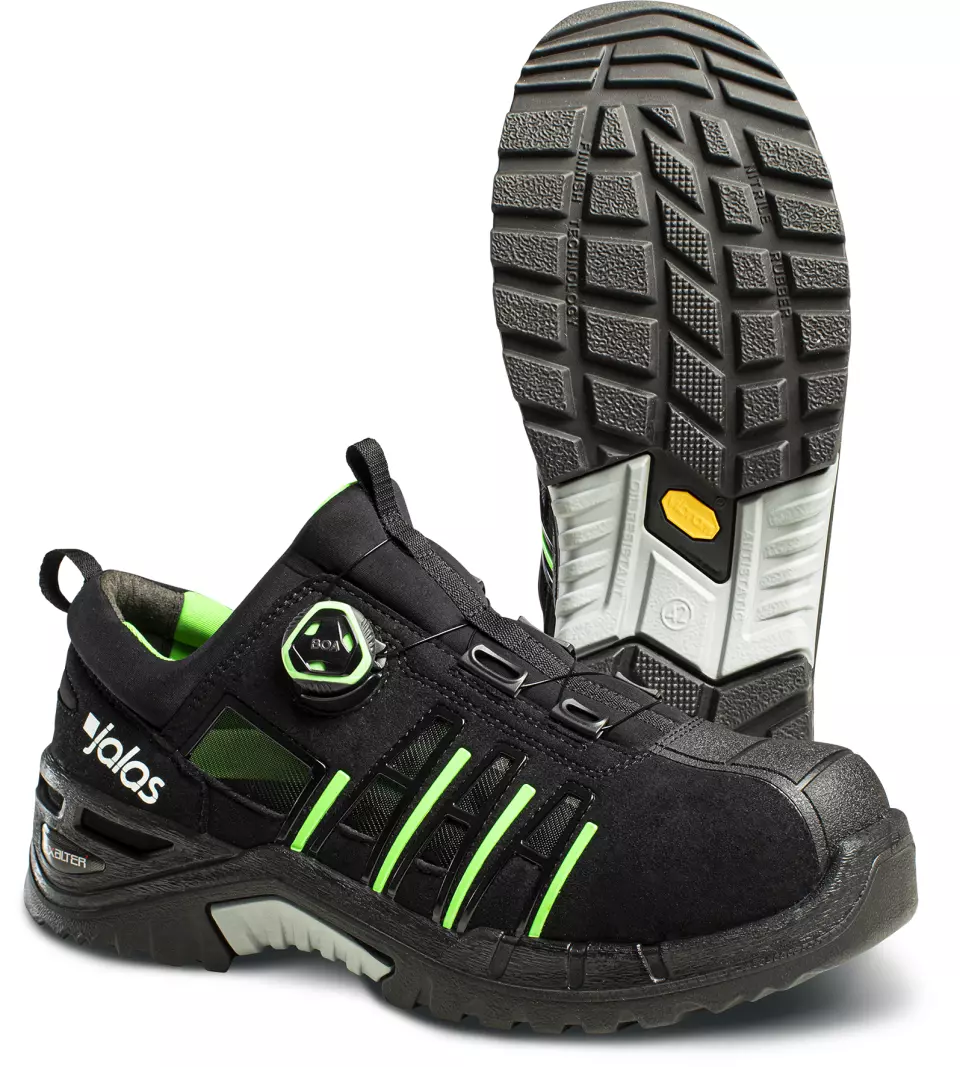

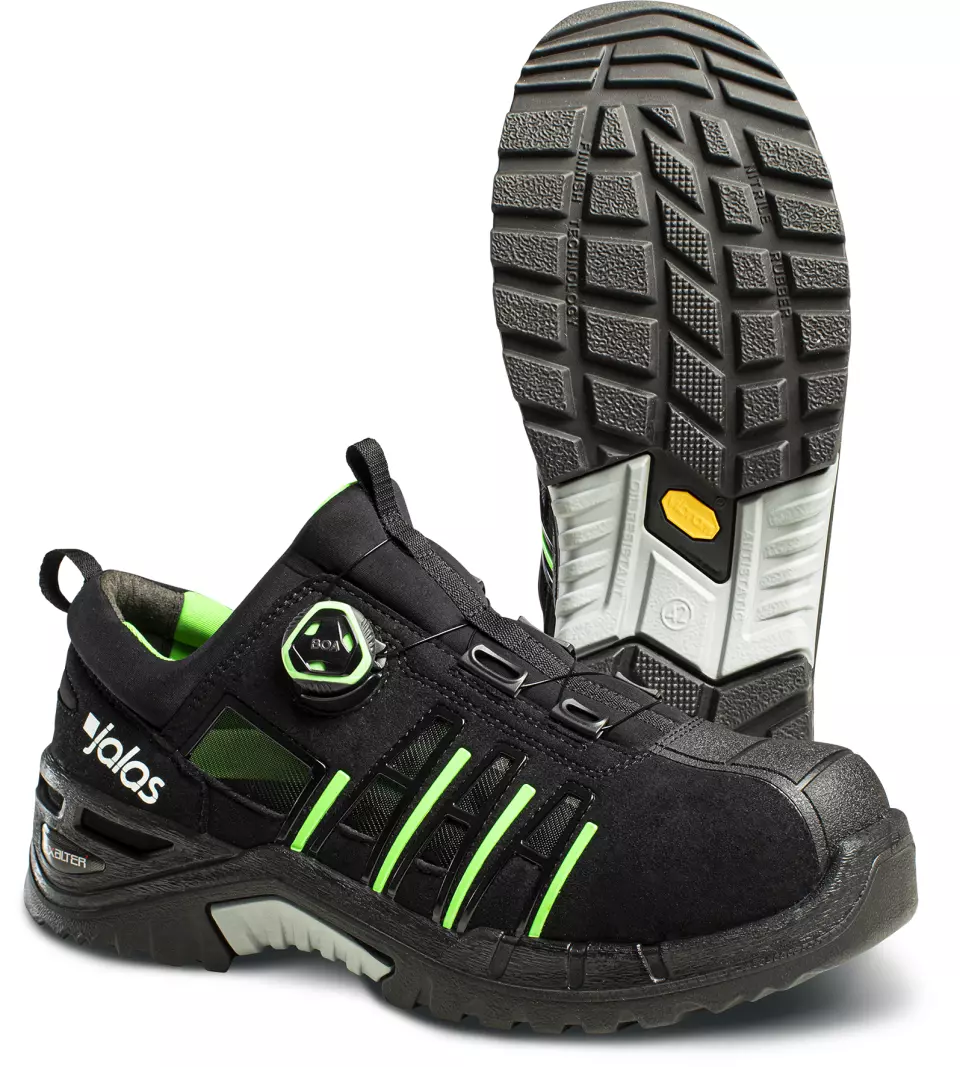

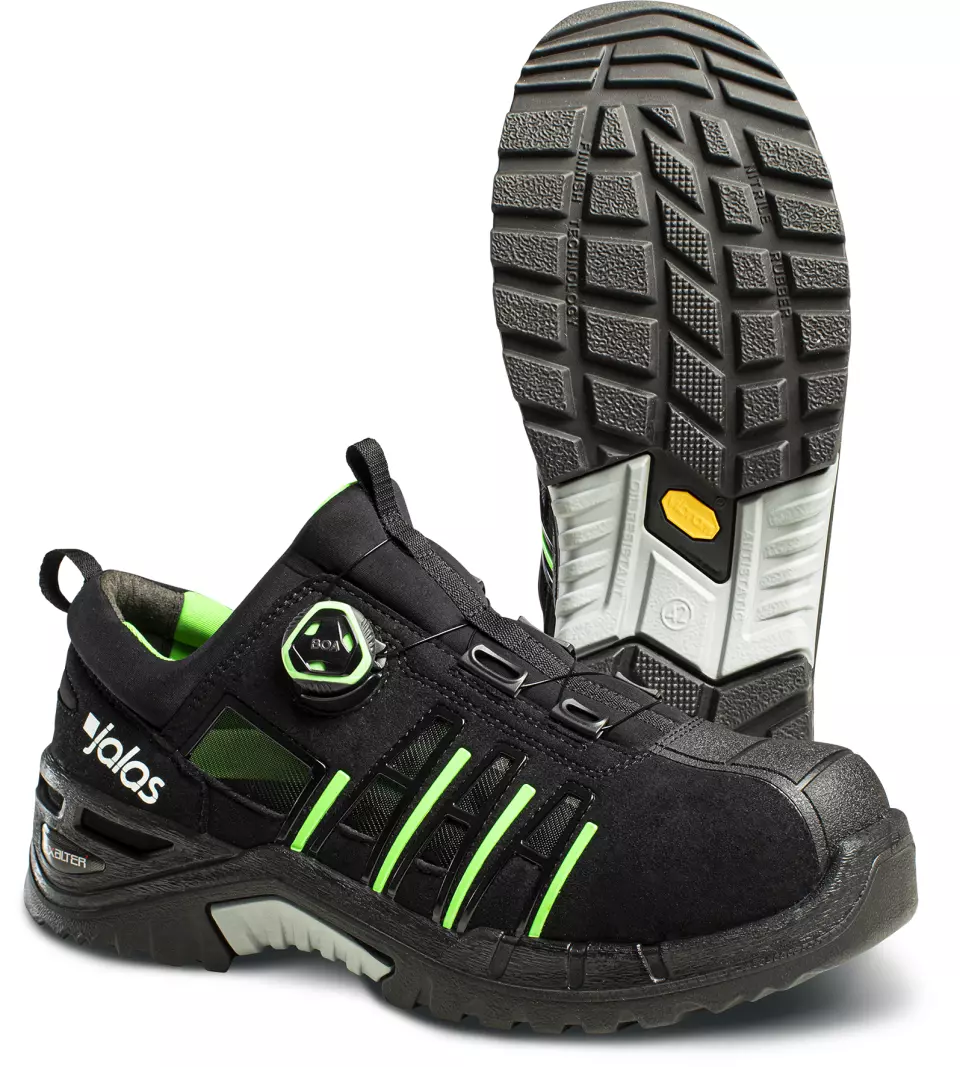

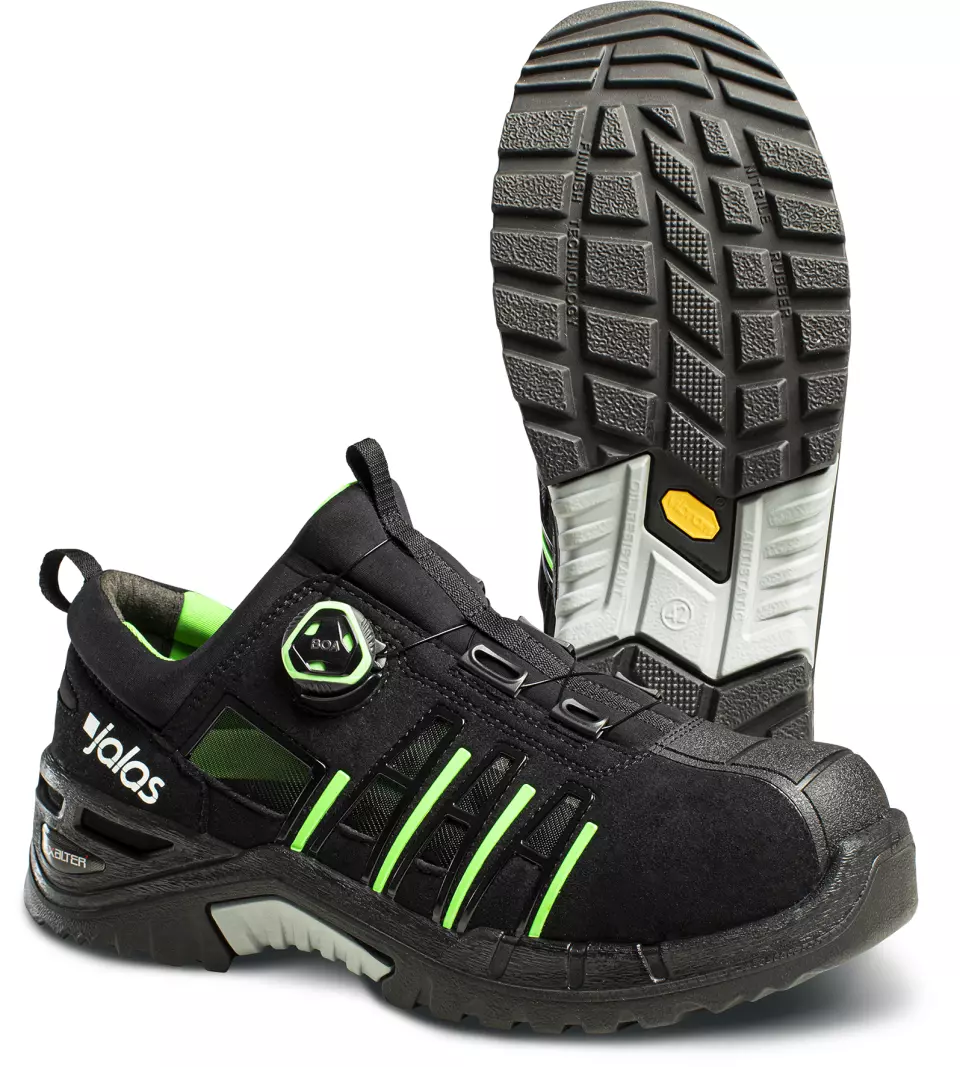

Product description

JALAS Exalter 9925, This low-profile safety shoe has everything you need for most work situations: a PTC textile spike protection, aluminium toe protection and a Vibram nitrile rubber sole. The midsole and the multi-layer JALAS FX3 Supreme insole, combined with the sock-like construction, provide the ultimate in comfort. PORON® XRD™ shock absorption prevents stress injuries to the foot and back. Mesh-lined vents in the upper keep feet cool and prevent particles from entering the footwear. BOA® fastening system for easy on and off.